Add to Cart

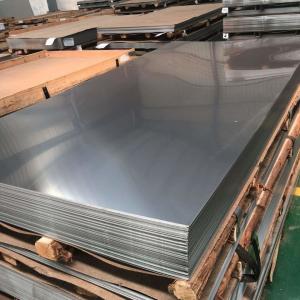

Durable 7075 T651 3 Gauge Aluminum Sheet For Truck Aviation Fixtures

Standard Cut Tolerance: -0'' to +1/8''

Precision cutting (+/- .005'') available. call for a quote

Our 7075 plate has T651 temper, indicating it has been solution heat treated followed by a minimal stretching to reduce stresses in the material. The material was then artificially aged to allow the alloying elements to precipitate out of the material, to give immediate maximum strength.

Quickly details.

1. Alloy: 7075

2. Temper: T6,T651.

3. Max length : 7500mm.

4. Width: 3.8m.

5. GB: 7075 GB/T3190--1996.

6. Russia standard:B95/1950 rocT 4785-1974.

7. EN AW-7075/AlZn5.5MgCu EN573-3-1994.

7075 T651 Aluminum Sheet Application:

7075 alloy aluminum sheet for Used to produce high-end aluminum alloy bicycle frame.

7075 alloy aluminum sheet for Aviation fixtures,

7075 alloy aluminum sheet for The truck,

7075 alloy aluminum sheet for Tower building,

7075 T651 Alloy Features:

1. Strong corrosion resistance of high stress structure.

2. Small grain make deep drilling performance better, tool wear resistance increase, more different thread rolling system.

3. Availability of product with porosity at class one .

7075 Alloy Aluminum Chemical Composition Standard.

| Cu | Mg | Mn | Fe | Si | Zn | Ti | Cr | Other | Al |

| 1.2-2.0 | 2.1-2.9 | 0.3 | 0.5 | 0.4 | 5.1-6.1 | 0.2 | 0.18-0.28 | <0.15 | Balance |

1. 7075 material is generally add a small amount of copper and chromium alloy, such as department of 7075 - T651 aluminum alloy is top grade, is praised as the most excellent products in aluminum alloy, high strength, much better than any of the mild steel. The alloy with good mechanical and anodic reaction. On behalf of the purpose of aerospace, mould processing, mechanical equipment, fixture, especially used in the manufacture of aircraft structures and other require high strength, strong corrosion resistance of high stress structure.

2. 7 series aluminum alloy is another common alloy, wide variety. It contains zinc and magnesium. More common in the aluminum alloy strength is best is 7075 alloy, but it can't be welded, a lot of parts manufactured by CNC cutting with is 7075 alloy. Zinc is the main alloying element in this series, plus a few magnesium alloy can make the material to heat treatment, to reach very high strength characteristics. This series of materials are generally add a small amount of copper and chromium alloy, which numbered 7075 aluminum alloy is top grade, the highest strength, suitable for the plane frame and high strength fittings.

We have available stock size for 7075 T651 as below:

| Alloy Series | Alloy | Temper | Thickness(MM) | Width(MM) | Length(MM) |

| Standard | 7075 | T651 | 10~120 | 1500 | 3000 |